Outsourcing the supply chain allows for greater operational and cost-related flexibility, but to be successful you have to choose a genuine strategic partner, and not just a simple supplier

A few weeks ago I participated in an event about logistics outsourcing, invited by ADL, the Association for the Development of Logistics, along with speakers from GrupoUno CTC and the legal firm Cuatrecases. The objective was to present the results of the 2nd Outsourcing Study in Spain and analyse the key points that companies should take into account when undertaking a process of this type. To do this, I shared the bittersweet experience we had with the outsourcing of the Bebitus logistics chain: the first attempt was a resounding failure, but with the second, we fully met all our objectives.

When Bebitus was founded in 2011 we opted to manage logistics internally, through our own warehouse, located in the same building as our offices. It seemed like a logical decision, for several reasons: we were just starting out, and we had a small inventory volume; we were still establishing our policies for delivery times, returns, etc; and we had the necessary know-how, due to my extensive experience in the field of logistics.

In fact, if we look at the logistics outsourcing index from the 2nd Outsourcing Study, we see that while 63% of Spanish companies turn to outsourcing their logistics, in SMEs this percentage drops to 49%. Therefore, we were what could be considered “normal” for a company that is starting out…

Problems with the internal management of logistics

During the early years, our commitment to internally managing the warehouse worked well. We achieved a leading position in the Spanish market, followed through on our commitment to deliver most orders in 24/48 hours, and incurred acceptable logistics costs. Having all the inventory on the ground floor is very convenient, and gives you a lot of peace of mind. However, the logistics management itself posed several problems..

The first one was the space required for the warehouse. As our stock grew, we needed larger and larger warehouses, which forced us to move further and further away from urban centres. Second, warehouse management required enormous dedication. As the CEO of Bebitus, there were days when I spent more time downstairs, overseeing the preparation of orders and the reception of merchandise, than above managing the company’s strategic aspects. Personnel management also took up more and more time, due to the increase in the staff required, and the turnover intrinsic to positions of this kind.

We had the goal of expanding our activity to Portugal and France while maintaining high levels of growth in the Spanish market. Inevitably, this meant that the dimension and resources devoted to managing internal logistics would continue to grow. Therefore, in 2015 we made the decision to fully outsource the Bebitus warehouse.

First unsuccessful logistics outsourcing attempt

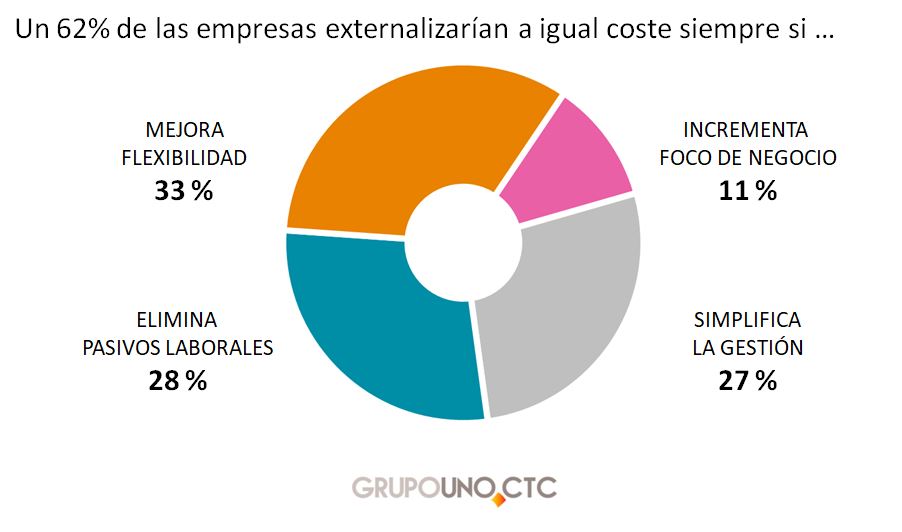

The reasons we opted for the outsourcing of Bebitus’s logistics cited above broadly overlap with the main reasons why companies outsource, as shown in the following graph from the 2nd Outsourcing Study by GrupoUno CTC.

62% of companies would outsource logistics at the same cost always if… Improves flexibility (33%); Eliminates labor liabilities (28%); Simplifies management (27%); Increases business focus (11%).

We also followed a process to select a outsourcing logistics partner based on the main criteria listed in the study: price (19%), the supplier’s reliability (16%), the flexibility of the management (14 %), image and experience (14%), etc.

But we made the wrong choice.

At the end of the selection process we had filed it down to two logistics outsourcing service companies that could, a priori, satisfy our requirements and fit into the range of costs we could afford. On paper, both offers were quite similar. Bebitus’s logistics manager at that time preferred one of the options; and I, as CEO and a “great” specialist in logistics, preferred another, as I explain in this video.

It was a serious mistake that almost spelled the end for Bebitus. From the beginning we realised that the partner we had chosen was not able to honour its commitments. In spite of its great reputation, the orders were piling up at the logistics center without being offloaded; deliveries of goods overloaded the docks, waiting to be received and checked in; shipments were late and of poor quality, generating dozens of claims, refunds and cancellations of orders. As if it were a prophecy, the main fears that stop companies from outsourcing their logistics were realised: loss of control, poor quality, negative brand image…

Customers began to complain on social media, and they had every reason to. In a short time we were spending most of our resources handling complaints and claims. Many days, at the end of their shifts, the employees at the Bebitus office went to the partner’s warehouse to lend a hand, to try to get as many orders as possible out. It was a really difficult few months, and I thought we would have to close Bebitus.

The second time’s the charm

After giving the outsourcing partner several opportunities to resolve the breakdowns in the provisioning of the service, we decided to take drastic measures: in 2016 we contacted the other company that had reached the final phase of the selection process to see if it could resolve the disastrous logistical situation in which we were mired.

As we had already put our foot in it once, and were leery, before signing the contract we gave the new partner the “third degree”. For days, we went to their logistics center and saw how they worked; we spoke with the staff at their facilities; we examined the preparation of the orders; we requested compliance metrics on the service levels; and we called other clients who had entrusted their logistics to this provider. In short, we did what we should have done with the first partner, instead of relying only on their reputation and their promises.

The in-depth analysis was satisfactory, and the new partner displayed absolute transparency. Thus, we ultimately rescinded the contract with the first provider and started working with the new one. The transfer from one warehouse to another was complicated, due to the chaotic situation that our logistics chain was going through at that time. However, we soon realised that this time we had made the right choice with our partner.

From the very outset the new partner went all out to deal with the overload and accelerate the dispatch of the pending orders. In a short time we were out of the rough patch, and back on track with our logistics. In the ensuing months we were on the rise again, and the partner was able to handle the increase in the number of orders without any trouble. Our partner was even proactive in proposing various improvements to optimise our supply chain’s capacity.

Finally, we were able to forget about the logistics, which was our main objective when outsourcing warehouse management in the first place, to focus on the strategic growth of the business at a time when our integration into Windeln.de had made us its subsidiary for all of Southern Europe. The difference? This time we had a genuine strategic partner that was engaged in the business, not just a provider who barely complied with its obligations.

In addition, with this new partner we began to really enjoy the other advantages offered by the outsourcing of logistics properly executed, in accordance with the findings of the GrupoUno CTC study: cost reduction (22%), greater flexibility (21%), improved productivity (18%), the meeting of new needs (10%), and fewer personnel management problems (10%). Undoubtedly, the outsourcing of the warehouse was one of the keys allowing Bebitus’ billing to skyrocket over the next two years, to over 40 million euros my final stage at this e-commerce company.

I believe that our story is an illustration of the benefits offered by the outsourcing of logistics, but also the fallout that a bad choice of partner can entail. Do not settle for finding a simple logistics provider. It is essential to find a strategic partner that takes an interest in and sees to the proper functioning of the supply chain, as much as the managers of the e-commerce company do, and more, as this is their responsibility.

In hindsight, I am certain that outsourcing the warehouse was one of the best strategic decisions we made during my time at Bebitus. I advise any e-commerce firm that wants to grow without having to worry about orders on a daily basis to do the same.

But, of course, it is a journey for which it is essential to choose the right partner!